| |

|

|

|

Media Information

Press Contact

Michelle Moody

Moody & Associates

+1-214-363-3460

|

|

|

CAP-XX Photo Gallery

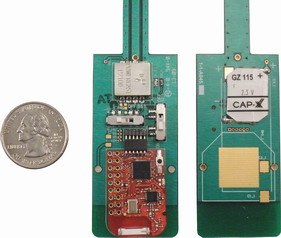

Pictured here with a US quarter dollar, CAP-XX

supercapacitors benefit from a unique nanotechnology construction, which packs the highest energy and

power-densities available today into thin, lightweight, prismatic packages (as little as 1mm thick). These

ultra-slim supercapacitors provide the peak power required for high brightness LED flash (BriteFlash™),

enhanced audio reproduction (BriteSound™) and many other applications (BritePower™). |

High Res |

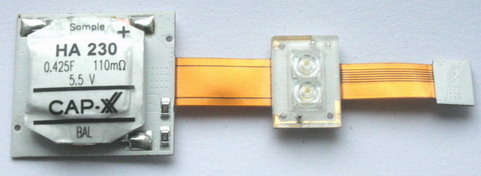

The key advantage of LED Flash over Xenon in camera

phones is size. An electrolytic capacitor is required for Xenon Flash and a slim supercapacitor powers an

LED Flash. For instance, a SonyEricsson K800 uses two electrolytic capacitors each measuring 7mm dia. x

18mm long. The CAP-XX LED BriteFlash™ solution uses two supercapacitors measuring

17mm x 39mm x 1.1mm side by side to keep the solution very thin” |

High Res |

|

BritePower™ Solutions/Devices Using Supercapacitors

|

| Powercast RF Energy Harvesting Module |

This wireless power module combines Powercast's

RF energy-harvesting technology with a CAP-XX supercapacitor to create a perpetual,

battery-free power source for the wireless sensors commonly used in security, environmental

and condition-monitoring systems. The module integrates a power receiving antenna, a

Powercast Powerharvester to convert the radio waves into low DC power and a CAP-XX

supercapacitor. The supercapacitor stores the harvested energy and provides peak

transmission power to a wireless sensor/transmitter board such as the Texas Instruments

eZ430-RF2500T. The complete module measures 8" tall x 1" wide x ¼” thick.

Contact Powercast at

www.powercastco.com for more information. |

Front and Back Close-up of Components

High Res |

|

Complete Module Including

Power

Receiving Antenna

High Res |

Perpetuum Vibration Energy Harvesting

Module

Perpetuum's PMG17 vibration energy-harvesting

micro-generator, together with a CAP-XX supercapacitor, allow wireless sensor system

manufacturers to design battery-free condition monitoring systems that collect and report data

on machinery for improved asset management. The PMG17 microgenerator converts unused

mechanical vibration into a low but steady source of electrical energy. The supercapacitor then

stores the energy and delivers the peak power needed to transmit sensor condition data over

wireless networks such as IEEE 802.15.4 (Zigbee) and 802.11 (WLAN). Together they can power

wireless sensor nodes indefinitely. Contact Perpetuum at

www.perpetuum.co.uk for more information. |

High Res |

|

| High-Power LED BriteFlash™ vs Xenon:

Camera Phone Flash Comparison |

Overview: This provides visuals from a 2009

study updating the company's 2006 study. Tests again showed that the LED BriteFlash approach

delivers more light energy than most xenon flashes in a thin form factor suitable for slim camera

phones and digital cameras. For more details and conclusions, see the press release:

http://www.cap-xx.com/news/FlashComparison.htm. |

The two photographs of the girl were taken in low light

from 2 meters distance to compare a small xenon flash in a current camera phone and the

supercapacitor-powered LED BriteFlash™ solution:

- Left: LG KU990 5-megapixel phone with a xenon flash unit delivers flash power so low

that the girl is barely visible as a silhouette.

- Right: Nokia N73 modified with CAP-XX BriteFlash solution - supercapacitor powers 3

LEDs at 1A each for a total flash power of 12W.

|

|

|

The two photographs of the colour scene with

metronome were taken in a dark room from 2 meters distance to compare a standard

battery-powered LED flash in a current camera phone and BriteFlash:

- Left: Nokia N96 with 2 LEDs but no supercapacitor support. Note the poor colour

reproduction from the colour chart. There is also a metronome ticking at 1Hz to show blur due to

exposure time 1/10s.

- Right: Nokia N73 modified with CAP-XX BriteFlash solution - supercapacitor powers 3

LEDs at 1A each for a total flash power of 12W. The colour chart shows much better colour rendition

and the metronome arm shows less blur from a faster exposure of 1/15s.

|

|

|

Light Power and Light Energy

Measurements: The key to clear pictures is Light Energy - the total amount of light that fills a

camera's pixels during image-capture time. On the other hand, Light Power refers to the intensity of

a flash. To calculate Light Energy: Light Power (Lux) x Flash Exposure Time (Secs) = Light Energy

(Lux.Secs).

- The Xenon flash has excellent light power, but a very short flash exposure time.

- An LED flash, powered by a supercapacitor, delivers lower light power over a longer

flash exposure time for total Light Energy that exceeds most Xenon flashes.

|

| Comparison of Light Energy between Xenon, BriteFlash and

Low-Power LED Flash |

| Source |

Storage

Capacitor |

Distance

(m) |

Peak Light

Power (lux) |

Exposure

Time

(msecs) |

Light

Energy

(lux.secs) |

Xenon

Samsung G800 |

Unknown |

1 |

303,000 |

<1 |

11.5 |

Xenon

SonyEricsson K800 |

2x 14µF |

1 |

217,000 |

<1 |

15.8 |

Xenon

Nokia N82 |

20µF |

1 |

161,000 |

<1 |

10.2 |

Xenon

LG KU990 (Viewty) |

10µF |

1 |

52,000 |

<1 |

2.6 |

BriteFlash

2x LEDs @ 2A each |

0.55F |

1 |

425 |

17 |

6.0 |

| 33 |

11.2 |

| 67 |

21.7 |

Medium power LED Flash

1x LED @ 1A |

0.55F |

1 |

135 |

67 |

8.9 |

Low power LED flash

2x LEDs, Nokia N96 |

NA |

1 |

30 |

67 |

2.15 |

| 100 |

3.45 |

Low power LED Flash

1x LED, Nokia N73 |

NA |

1 |

20 |

90 |

1.71 |

| |

|

|

|

|

|

Xenon

Samsung G800 |

Unknown |

2 |

72,000 |

<1 |

2.90 |

Xenon

SonyEricsson K800 |

2x 14µF |

2 |

57,000 |

<1 |

4.45 |

Xenon

Nokia N82 |

20µF |

2 |

40,000 |

<1 |

2.45 |

Xenon

LG KU990 (Viewty) |

10µF |

2 |

15,000 |

<1 |

0.72 |

BriteFlash

2x LEDs @ 2A each |

0.55F |

2 |

130 |

17 |

1.9 |

| 33 |

3.6 |

| 67 |

7.0 |

Low power LED flash

2x LEDs, Nokia N96 |

NA |

2 |

8.2 |

67 |

0.55 |

| 100 |

0.86 |

Low power LED Flash

1x LED, Nokia N73 |

NA |

2 |

5.0 |

90 |

0.43 |

| |

|

|

|

Flash Solutions Tested:

- Xenon: SonyEricsson K800, LG KU990, Nokia N82 and Samsung G800 all with 5-megapixel

cameras but with varying size electrolytic storage capacitors.

- Standard battery-powered LEDs: Nokia N73 (3.2-megapixel) and N96 (5-megapixel).

- Supercapacitor-powered LEDs: To demonstrate the BriteFlash approach, CAP-XX used a small,

thin (20mm x 18mm x 3.8mm thick), dual-cell supercapacitor to drive a two-LED array of Philips

LUXEON® PWM4s at 2A each or 4A total during the flash pulse.

|

Comparison of Solution Size and Energy

Density

The key advantage of LED Flash over Xenon in camera phones is size. The image on the

right compares the electrolytic capacitor used in the SonyEricsson K800 and the supercapacitor used for

the LED Flash. The SonyEricsson K800 uses two of these electrolytic capacitors each measuring 7mm

dia. x 18mm long. Similarly, the LED Flash solution uses two of these supercapacitors measuring 17mm x

39mm x 1.1mm side by side to keep the solution very thin. |

|

The bulky electrolytic capacitor

precludes a thin form factor for a Xenon flash solution with adequate

light energy.

Pictured is the SonyEricsson K800. The internal shot shows two electrolytics fitted inside and the

other shows the electrolytic and supercapacitor in profile next to the phone. |

|

|

|

|

Size comparison between prismatic

supercapacitor and cylindrical electrolytic storage capacitor used for xenon flash. The SonyEricsson

K800 uses two of these electrolytics; the Nokia N82 uses one of the same size.

|

Xenon

|

Supercapacitor-enabled

LED flash (BriteFlash)

|

Bulky:

- Large electrolytic storage capacitor

- Total volume of xenon solution in SonyEricsson K800 ~3.8cc and 7mm thick |

Small and thin:

- Prismatic supercapacitor

and LEDs

- Typically < 2cc and 2 - 4mm thick 1 |

Fragile (Drop test):

- Xenon tube

- Electrolytic connection to flex PCB prone to fracture due to large mass of capacitors

and flimsiness of PCB |

Rugged (no difficulties with drop test):

- No large mass

- No fragile parts |

Safety:

1.5J of energy stored at 330V can

give a nasty shock, particularly near the ear |

Safe:

Low voltage, no safety issues |

| High Voltage (HV) trigger circuit needed for xenon

flash tube, > 4000V. Special measures and/or clearance is required to prevent arcing to other

circuits |

No HV, no special steps to prevent arcing to other

circuits |

| Mechanical shutter required to prevent

overexposure: extra cost, size & power |

Works with a rolling shutter. No mechanical shutter

required |

| High voltage and current pulse for xenon strobe

causes Electro Magnetic Interference (EMI) |

High current delivered from supercap,

EMI easier to manage |

| Still need a separate LED for video/torch mode |

Same LEDs used for flash and video/torch |

| Long time to re-charge electrolytic capacitor between

photos (~8s for SonyEricsson K800) |

Short time to re-charge supercapacitor

between photos (~2s) |

| Electrolytic capacitor cannot be used for any other

peak-power needs |

Supercapacitor can be used to meet all peak power needs

in the cell phone including:

- Flash pulse

- GPS readings

-

RF Transmission for GPRS

- Audio |

Very high-powered light delivered in >

200µsec:

- No photo blur

- Can take an action shots in low light |

Light energy delivered over longer time:

-

Capable of high-quality still shots, but cannot take action shot in low light

-

Image stabilization software can correct for hand movement |

| High Res JPG Version |

| 1Thickness will depend on implementation: two

single-cell supercapacitors side by side (double the footprint and half the thickness), or a dual-cell

supercapacitor with the two cells stacked on top of each other (half the footprint and double the

thickness) |

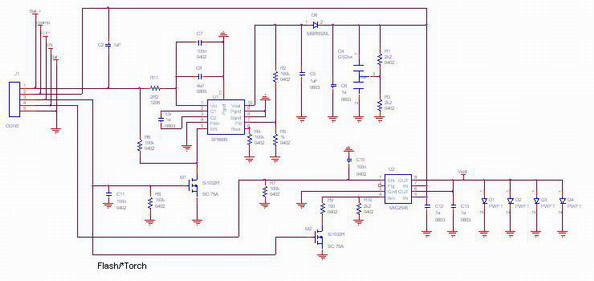

To achieve high LED power, designers can add a thin

supercapacitor to deliver peak flash-power, using the battery to cover average power needs

and recharge the supercapacitor between flashes. Integrating the circuitry outlined in blue (boost

converter, supercapacitor balancing, I2C interface and LED current control), new

supercapacitor-optimized LED flash drivers from major IC companies such as AnalogicTech and ON

Semiconductor are now available to save time, board space and component cost. A white paper

explains

more at

http://www.cap-xx.com/resources/pres_wp/pres_wp.htm#wp.

|

Supercapacitor-enabled LED

Flash Modules |

This supercapacitor-powered LED flash module reference design (pictured below), developed

by Seoul Semiconductor, uses a thin, prismatic HA230 CAP-XX supercapacitor and an

AnalogicTech AAT1282 LED flash driver (on reverse side) to drive high-current Seoul Semiconductor

LEDs. To discuss this module with Seoul Semiconductor, contact Jesper Bennike,

Technical Sales and Solution Manager

Mobile: +45 22951550

Office: +45 38887550

Jesper@Seoulsemicon.com

|

|

|

High Res |

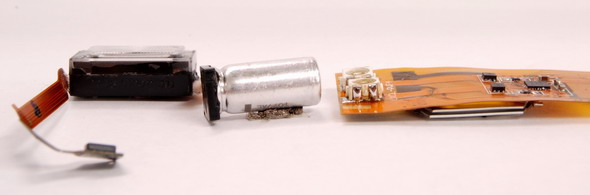

The supercapacitor-powered LED flash

module reference design (pictured below right), developed by ON Semiconductor, uses a thin

CAP-XX HA230 supercapacitor (on the underside) and the ON Semiconductor NCP5680 flash

driver to drive high-current Lumileds LEDs. Also pictured (left) for comparison is the Nokia N82

xenon flash solution with its large, cylindrical electrolytic capacitor.

|

|

|

High Res |

|

BriteFlash™ in Action

|

To demonstrate the increased flash power and ease of design-in, CAP-XX engineers retrofitted

several industry-leading camera phones with the BriteFlash™ solution. In this phone, CAP-XX

added a ~1.2mm thick dual-cell supercapacitor [highlighted in red], replaced existing LEDs with 4

high-powered LEDs that can each handle a peak pulse current of 1A, then put the phone together again

with no change in external appearance. The original phone delivered 1 watt of flash power for 160

milliseconds while the CAP-XX-modified phone delivered 15 watts for the same amount of time. |

|

| High Res JPG Version

High Res TIF Version

|

|

CAP-XX placed two supercapacitor cells and four replacement LEDs in a

leading-brand camera phone to demonstrate its flash power. The photos below were taken using the

unmodified phone on the left and the CAP-XX-modified phone on the right. The unmodified phone

delivered 1W of flash power for 160ms while the modified phone delivered 15W of flash power for 160ms.

|

|

|

|

High Res |

High Res |

|

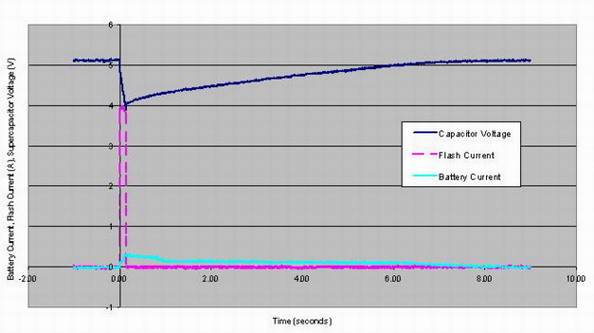

The graph below shows the Battery Current, LED Current, and

Supercapacitor Voltage during a flash pulse and supercapacitor recharge after the pulse. Note that the

Battery Current never exceeds 300mA even though the flash pulse is 4A. The supercapacitor provides

the 3.7A difference. |

|

|

High Power LED Supercapacitor

Solution Reference Design |

|

|

High Res |

|

|

BriteSound™ Power Architecture for Music Phones |

Pump up the volume!

Supercapacitors enhance audio quality and power in mobile phones.

As multimedia and music phones grow in popularity, consumers want an iPod-quality audio

experience without the buzzing and distortion associated with wireless transmissions. In the

BriteSound™ power architecture, CAP-XX supercapacitors double audio power for richer-sounding

music and handle peak power demands to eliminate distortion during wireless transmissions.

|

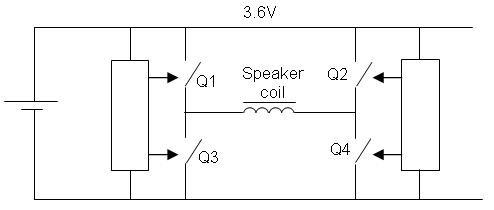

Audio Quality Problems in Music Phones |

Typically, a standard 3.6-volt battery powers two class D amplifiers

to drive a pair of 8-ohm speakers.

For the problems with this typical set-up, see

white paper. |

|

| Fig 1: Typical configuration for class D amplifier |

|

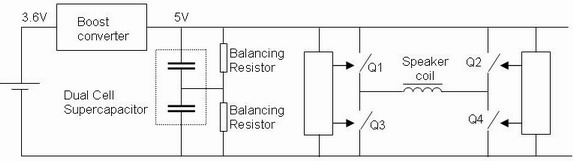

| Managing Mobile Phone Audio Power with a Supercapacitor |

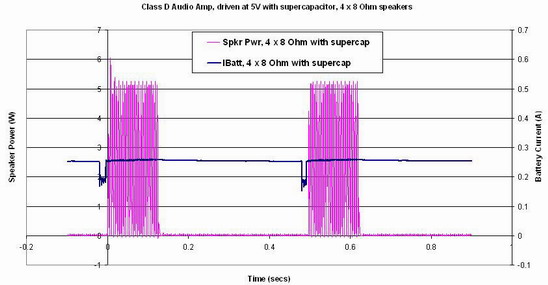

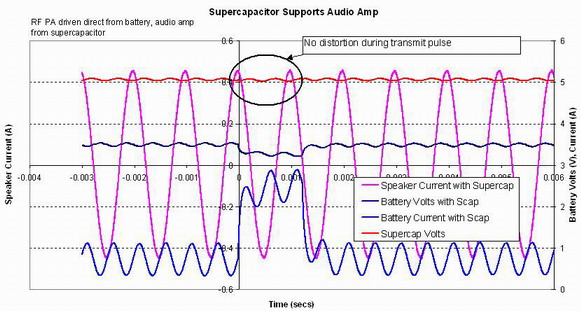

In the BriteSound™ power architecture, a 2.4mm-thin,

0.55-farad, 85-milliohm dual-cell CAP-XX HS206 supercapacitor delivers 5W power-bursts to drive

peak-power functions such as audio and LED Flash.

A battery covers the phone's average audio power needs of 0.5 to 1W, recharging the supercapacitor

between bursts. This leaves enough battery power to handle data transfers and network polls without

compromising audio power, eliminating both the distortion and "clicks" normally heard.

The supercapacitor powers the audio amplifier at 5 volts, compared to 3.6 volts directly from a battery,

thereby doubling peak audio power for full-sounding music with a strong bass beat.

The supercapacitor also reduces noise by supplying peak power with less voltage droop than the

battery would, and eliminates any 217Hz buzz when a GSM/GPRS/EDGE phone transmits by protecting

the audio amplifier from other peak loads the battery supplies such as the RF Power Amplifier.

Because the supercapacitor supplies high-peak currents, designers can use higher-quality 4-ohm

instead of standard 8-ohm speakers, further doubling peak audio power. |

|

| Fig 2: Class D amplifier with supercapacitor |

|

| Tests Comparing Mobile-Phone Audio Quality and Power |

CAP-XX used three cases for comparing audio quality and power,

testing typical mobile-phone audio circuits both with and without a supercapacitor. To test the

difference in power that 4-ohm versus 8-ohm speakers would make, CAP-XX simulated the effect by

attaching a second set of identical 8-ohm speakers in the supercapacitor-powered set-ups.

To test a bass beat and a network poll, CAP-XX built 2 test circuits each with two class D audio

amplifiers, one powered by a battery to drive a pair of 8-ohm speakers, the other supported by a

supercapacitor to drive two pairs of 8-ohm speakers. |

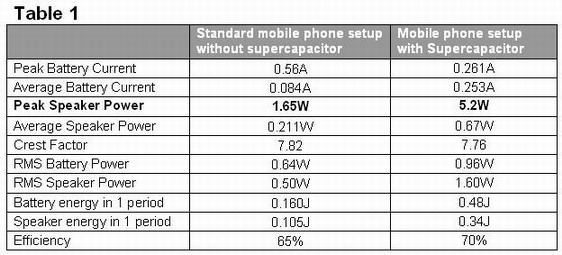

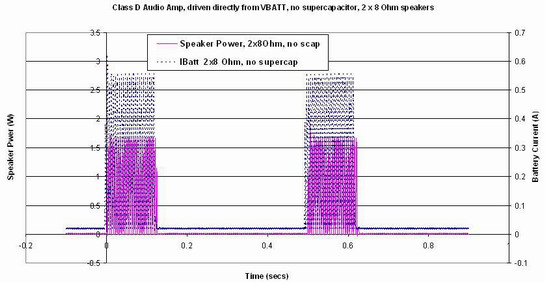

Bass Beat |

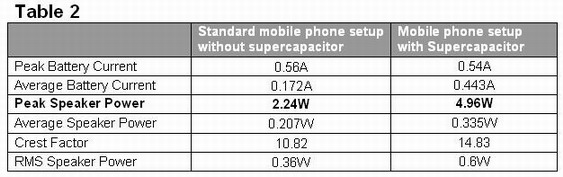

CAP-XX used a 100Hz bass beat lasting 120 milliseconds

repeated every 0.5 seconds to test speaker power and battery current. The supercapacitor

tripled peak audio power from 1.65W to 5.2W for fuller-sounding music. Test results are

shown below in Table 1 and Figures 3 and 4. For more technical details,

see

white paper.

|

|

|

|

|

| Fig 3: Bass beat, no supercapacitor |

|

|

| Fig 4: Bass beat with supercapacitor |

|

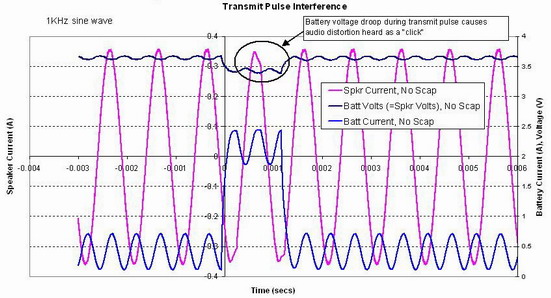

| Network Poll |

CAP-XX simulated a GSM/GPRS/EDGE network poll while listening to music by applying a

two-amp, 1.15-millisecond power pulse while the audio amplifier was playing a 1KHz tone. The

supercapacitor protected the audio amplifier from the battery voltage droop, eliminating distortion during

wireless transmission. Test results are shown below in Figures 5 and 6. For more technical details,

see

white paper. |

|

|

| Fig 5: Distortion in audio when battery needs to supply

peak current for audio + RF PA. |

|

|

| Fig 6: Supercapacitor buffers the audio amp from battery voltage

droop during the RF transmit pulse, so there is no audio distortion |

|

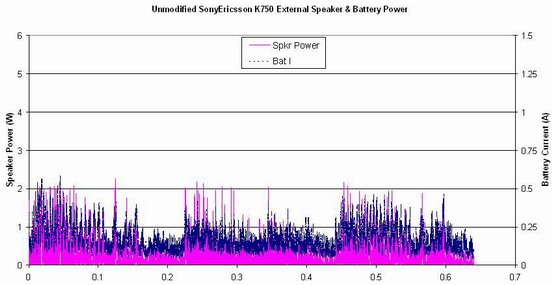

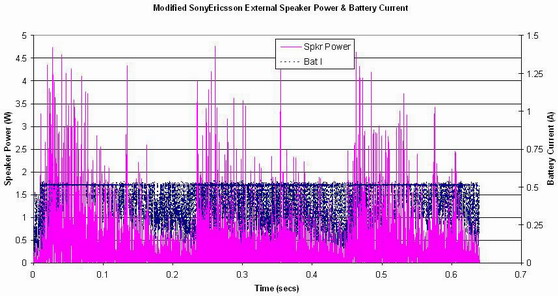

| Listening to a Piece of Music |

CAP-XX used a set of SonyEricsson MPS60 external speakers and audio amplifier as a test

bed. Engineers modified one set with a supercapacitor charged to 5V to power the audio amplifier, then

connected a second pair of 8-ohm speakers to the original pair. Figures 7 and 8 below show the

modifications.

The company played a piece of music to compare the unmodified MPS60 to the

supercapacitor-powered one. The supercapacitor-modified setup more than doubled peak

audio power from 2.24W to 4.96W, so music sounded fuller and richer. Test results are shown

below in Figures 9 and 10 and Table 2. For more technical details, see

white paper. |

|

|

| Fig 7: External audio amplifier, powered from the phone,

modified to include a supercapacitor |

|

|

Fig 8: Modified external speaker set including a second pair of

speakers

connected in parallel to the original pair. |

Figures 9 & 10 compare battery current and speaker power between the standard set of

speakers and our modified set for a piece of music.

|

|

Fig 9: Battery current and speaker power while playing music,

standard setup

driving 2 x 8 speakers with audio amp powered from Vbatt. |

|

|

Fig 10: Battery current and speaker power while playing music,

modified setup

driving 4 x 8 speakers with audio amp powered from a supercapacitor at 5V.

|

|

|

|

|

|

|